目录

ToggleWhat is box build in PCB and how’s the process?

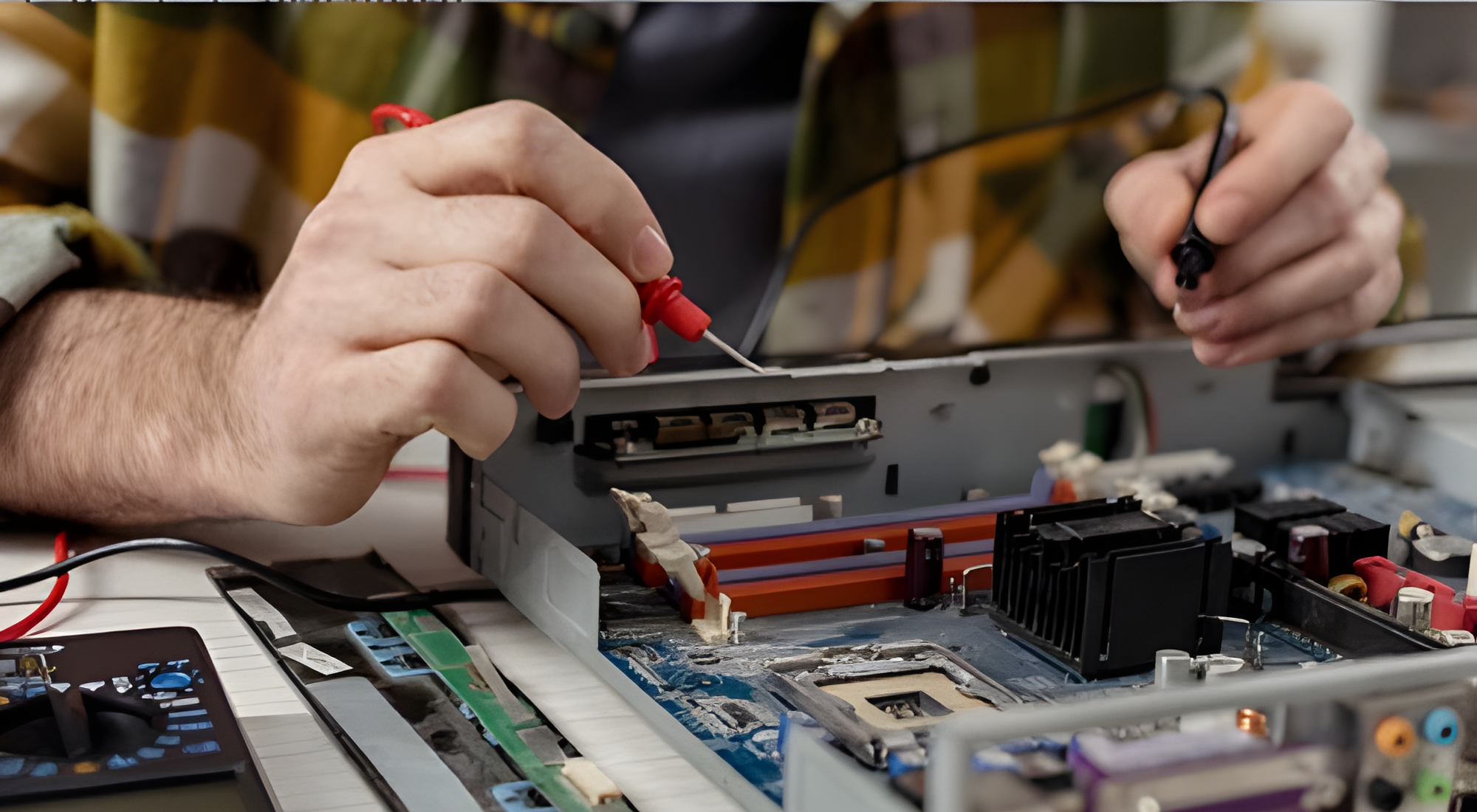

Box build in PCB refers to the process of PCB assembling and enclosing a printed circuit board (PCB) within a protective housing or enclosure. It involves integrating the PCB board, along with its associated electronic components, into a complete and functional electronic device.

The box building process typically includes the following steps:

- Housing Selection: A suitable housing or enclosure is chosen based on the specific requirements of the electronic device. The housing should provide physical protection, accommodate the PCB and its components, and allow for proper ventilation and access to external interfaces.

- PCB Mounting: The PCB is securely mounted inside the housing using screws, standoffs, or other mounting mechanisms. The mounting method ensures that the PCB is held firmly in place and properly aligned within the enclosure.

Electronic Component Integration: The electronic components that are not directly mounted on the PCB, such as switches, connectors, displays, and user interface elements, are integrated into the housing. These components are connected to the PCB through wiring or cable assemblies.

- Wiring and Cable Assembly And Routing: The necessary wiring and cables are routed within the enclosure to establish electrical connections between the PCB and the integrated components. Careful attention is given to proper cable management to ensure efficient use of space and to minimize the risk of interference or damage.

- Power Supply and Connectivity: The power supply components, such as transformers, power regulators, and connectors, are installed within the enclosure. External connectors for power input, data communication, and other interfaces are also integrated into the housing.

- Mechanical Assembly: If the electronic device requires mechanical components, such as buttons, knobs, hinges, or structural elements, they are assembled within the enclosure. This step ensures that the device has the necessary mechanical functionality and user interaction features.

- Testing and Quality Control: The assembled device undergoes testing to verify its functionality, performance, and compliance with specifications. This includes electrical testing, functional testing, exterior inspectionand any specific tests related to the device’s intended use.

- Final Finishing: Once the device passes the testing phase, final finishing touches are applied. This may include labeling, branding, applying protective coatings, and ensuring that the device meets any regulatory or safety requirements.

The box building process is crucial in transforming a bare PCB into a fully functional electronic device. It involves integrating the PCB, components, wiring, and mechanical elements within a protective enclosure to create a finished product that is ready for use by end-users.

Box build benefits:

Box build assembly offers several benefits in the manufacturing and assembly of electronic devices.

- Simplified Supply Chain Management: Box build assembly consolidates multiple components and subsystems into a single assembly, reducing the complexity of the supply chain. Instead of managing and coordinating the sourcing, procurement, and assembly of individual components, a single box build assembly can be outsourced to a contract manufacturer, streamlining the logistics and reducing administrative overhead.

- Time and Cost Savings: By outsourcing the box build assembly to a specialized contract manufacturer, companies can save time and costs associated with in-house assembly. Contract manufacturers have expertise in efficient assembly processes, economies of scale, and access to specialized equipment, resulting in faster production cycles and potentially lower manufacturing costs.

- Improved Quality Control: Box build assembly allows for better quality control and consistency in the manufacturing process. Contract manufacturers often have stringent quality control measures in place, including inspection, testing, and compliance with industry standards. This helps ensure that the final product meets the required quality standards and specifications.

- Design Flexibility: Box build assembly provides design flexibility, allowing for customization and integration of various components and subsystems. It enables the integration of PCBs, wiring, connectors, displays, user interfaces, and mechanical components into a single enclosure, resulting in a compact and cohesive product design.

- Reduced Time to Market: Outsourcing box build assembly can help accelerate time to market for electronic devices. By leveraging the expertise and resources of a contract manufacturer, companies can expedite the assembly process, optimize production schedules, and quickly bring their products to market, gaining a competitive edge.

- Scalability: Box build assembly offers scalability in production. Contract manufacturers can accommodate varying production volumes, from small-scale prototypes to large-scale production runs. This scalability allows companies to meet market demand efficiently without investing in additional manufacturing infrastructure or resources.

- Focus on Core Competencies: Outsourcing box build assembly allows companies to focus on their core competencies, such as product design, research and development, and marketing. By delegating the assembly process to a contract manufacturer, companies can allocate their resources and expertise to areas that directly contribute to their competitive advantage.

Overall, box build assembly provides numerous benefits, including streamlined supply chain management, cost and time savings, improved quality control, design flexibility, reduced time to market, scalability, and the ability to focus on core competencies. These advantages make box build assembly an attractive option for companies looking to optimize their manufacturing processes and bring high-quality electronic devices to market efficiently.

Topfast PCB always been committed of high-quality PCB productions such as high-speed PCB, high-frequency PCB, metal PCB and ceramic PCB, not only for the PCB production but also for the PCB assembly (PCBA) we have been adhering to the basic guidelines of the high standard of strict requirements, no matter in the surface mount technology(SMT), through hole technology (THT) or the box building assembly, will be after at least 3 times of testing and checking, in order to ensure the qualified rate of all products at least 97%.

Welcome to contact us if you have any requests on PCB manufacturing or PCB Assembling.We will answer you within 2 hours.

Electronic Component Integration: The

Electronic Component Integration: The