目录

ToggleAdvancements in PCB Technology: From Through-Hole to Surface Mount

Introduction to PCB Technology Evolution

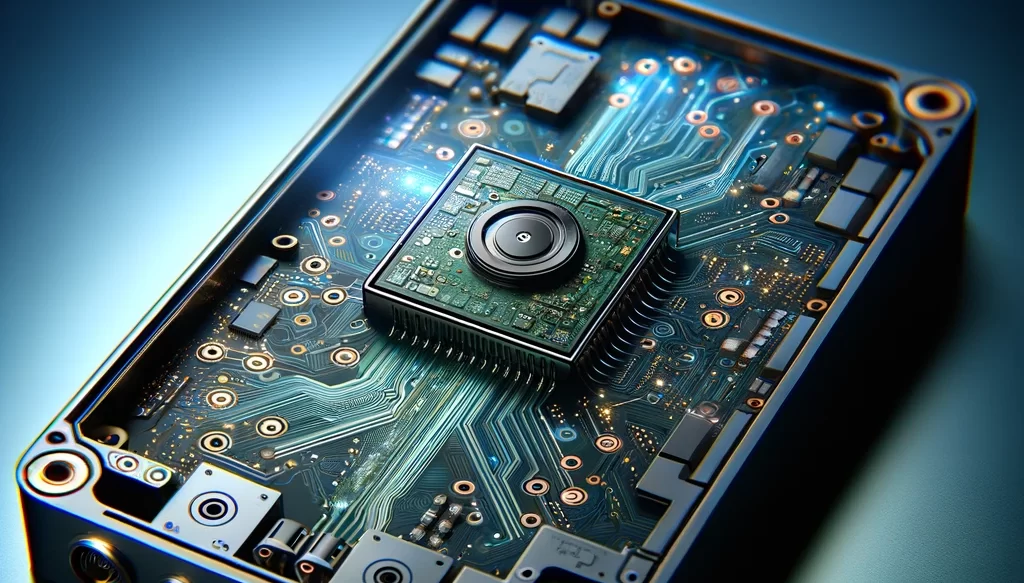

The evolution of PCB (Printed Circuit Board) technology from through-hole to surface mount has significantly transformed electronic manufacturing. This article explores this transition, highlighting the advancements and impact on the industry.

The Era of Through-Hole Technology

Through-hole technology, the traditional method of PCB assembly, involves inserting components with leads into pre-drilled holes. We’ll delve into its history, advantages, and the reasons it was eventually surpassed by surface mount technology.

Introduction to Surface Mount Technology (SMT)

Surface mount technology revolutionized PCB design by allowing components to be mounted directly onto the surface of the board. This section introduces SMT, explaining its principles and how it differs from through-hole technology.

Efficiency and Compactness of SMT

SMT offers enhanced efficiency and compactness compared to traditional methods. Here, we compare these two techniques, focusing on the benefits of SMT in terms of space utilization and manufacturing speed.

SMT in Practice

This part showcases the practical application of SMT, including the skills required for precision and accuracy in this technology. We also discuss the challenges and solutions in implementing SMT in PCB manufacturing.

Conclusion

The transition from through-hole to surface mount technology marks a significant leap in PCB manufacturing. It not only enhanced the efficiency and compactness of PCBs but also paved the way for further innovations in electronic design.

-

Optimizing Signal Integrity in Multi-layer PCBs for High-Speed Data Transfer

-

Optimizing Thermal Management in High-Density PCB Layouts

-

Advanced Techniques in High-Frequency PCB Design for 5G Applications

-

Eco-Friendly Approaches in PCB Manufacturing: Reducing Environmental Impact

-

Emerging Trends in PCB Manufacturing: From Traditional Methods to Cutting-Edge Innovations