目录

ToggleIntroduction: Unraveling the Differences: PCB, PCBA, and SMT

In the world of electronics manufacturing, there are several terms that often get thrown around, leaving many people confused about their meanings and relationships. Three such terms are PCB, PCBA, and SMT. While they may sound similar, they actually refer to distinct aspects of the manufacturing process. Understanding these distinctions is crucial for anyone involved in the electronics industry. In this article, we will delve into the differences and relationships between PCB, PCBA, and SMT, shedding light on their roles and importance.

PCB (Printed Circuit Board): The Foundation of Electronic Devices

A Printed Circuit Board (PCB) is the backbone of any electronic device. It is a flat board made of non-conductive material, such as fiberglass or composite epoxy, with conductive pathways etched or printed onto it. These pathways, known as traces, connect various electronic components on the board, allowing them to communicate and function together.

PCBs come in various shapes and sizes, depending on the complexity and requirements of the electronic device they are intended for. They can be single-sided, with components mounted on one side only, or double-sided, with components mounted on both sides. Additionally, there are multi-layered PCBs, which have multiple layers of conductive traces separated by insulating material.

The importance of PCBs cannot be overstated. They provide mechanical support to the components, ensuring their stability and protection. Moreover, PCBs enable efficient and reliable electrical connections between the components, reducing the risk of short circuits or other electrical failures. Without PCBs, the intricate electronic devices we rely on today would not be possible.

PCBA (Printed Circuit Board Assembly): Transforming PCBs into Functional Devices

While PCBs serve as the foundation of electronic devices, they are not functional on their own. To transform a PCB into a fully operational device, it needs to undergo the process of Printed Circuit Board Assembly (PCBA). PCBA involves the attachment of electronic components, such as resistors, capacitors, integrated circuits, and connectors, onto the PCB.

The PCBA process is a delicate and precise operation that requires specialized equipment and skilled technicians. Components are soldered onto the PCB using various techniques, such as through-hole soldering or surface mount technology (SMT). Once the components are securely attached, the PCB is ready to be tested and integrated into the final product.

SMT (Surface Mount Technology): The Key Process in PCBA Manufacturing

Surface Mount Technology (SMT) is a crucial process within the PCBA manufacturing process. It involves the mounting of electronic components directly onto the surface of the PCB, without the need for drilling holes or leads. SMT has revolutionized the electronics industry by enabling smaller, lighter, and more efficient devices.

SMT components are typically smaller and more compact than their through-hole counterparts, allowing for higher component density on the PCB. This increased density translates into smaller and more portable devices. Additionally, SMT offers improved electrical performance, as the shorter connection paths reduce signal loss and interference.

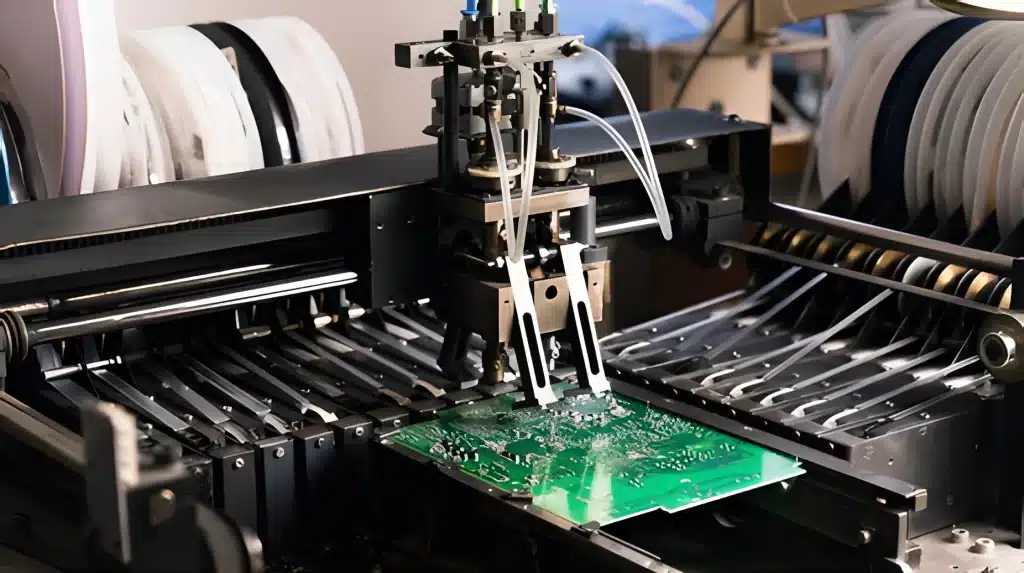

The SMT process involves the use of automated machines, known as pick-and-place machines, which precisely position the components onto the PCB. The components are then soldered onto the PCB using reflow soldering, where the entire assembly is heated to melt the solder and create a secure bond. This automated process ensures accuracy, speed, and consistency in the assembly process.

In conclusion, understanding the distinctions and relationships between PCB, PCBA, and SMT is essential for anyone involved in the electronics industry. PCBs serve as the foundation of electronic devices, providing mechanical support and electrical connections. PCBA transforms PCBs into functional devices by attaching electronic components. SMT, a key process within PCBA manufacturing, enables the mounting of components directly onto the PCB surface, resulting in smaller and more efficient devices. By unraveling these differences, we gain a deeper appreciation for the intricate processes that bring our electronic devices to life.

https://www.tf-pcb.com/services/pcb-assembly/

https://www.facebook.com/profile.php?id=100086889766737