目录

ToggleCustomized Excellence: PCB ODM Services

Introduction:

In today’s competitive electronics industry, companies seek tailored solutions to meet their specific requirements efficiently. This article delves into the realm of PCB ODM services, exploring how customized excellence drives innovation and success in the field of printed circuit board manufacturing.

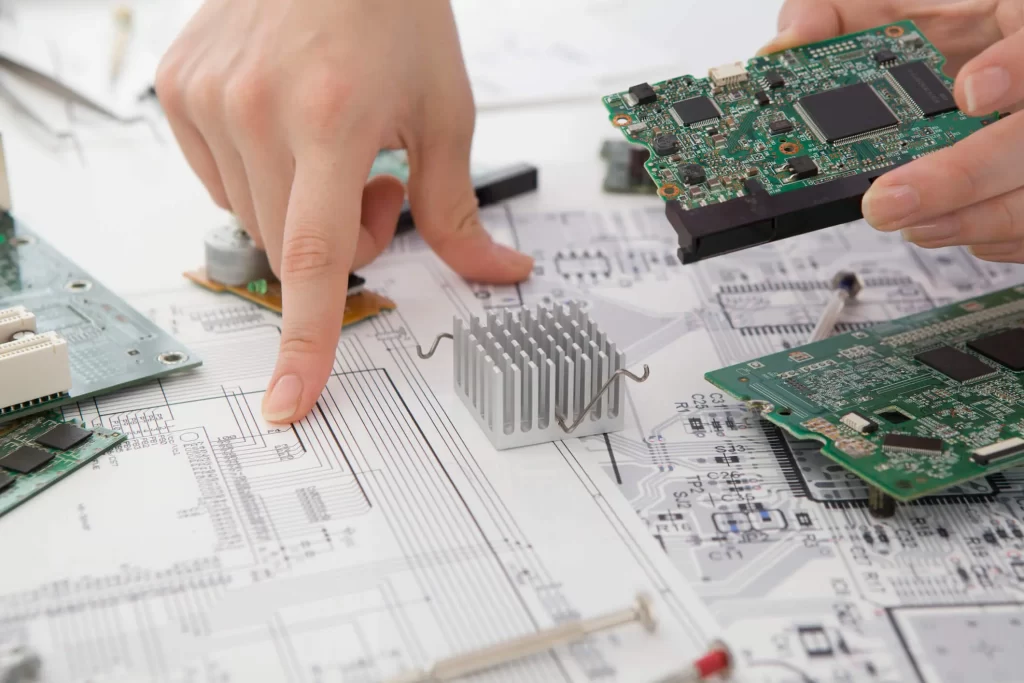

Understanding PCB ODM Services:

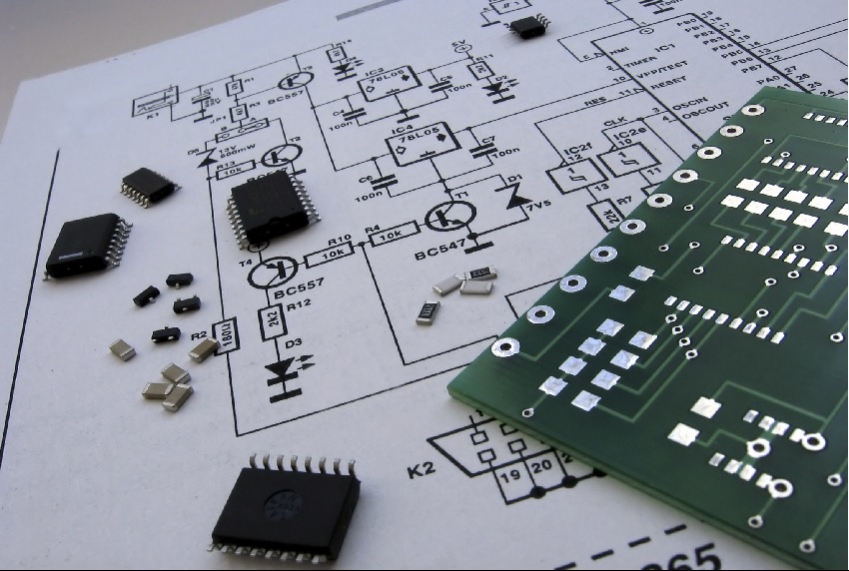

PCB Original Design Manufacturing (ODM) services cater to clients’ unique needs, offering customized solutions from concept to production. These services encompass design, prototyping, testing, and mass production, providing a comprehensive approach to PCB development.

Benefits of Customized Solutions:

Customized PCB solutions offer several advantages, including optimized performance, enhanced functionality, and cost-effective production. By tailoring designs to specific requirements, ODM services ensure compatibility, reliability, and scalability for diverse applications.

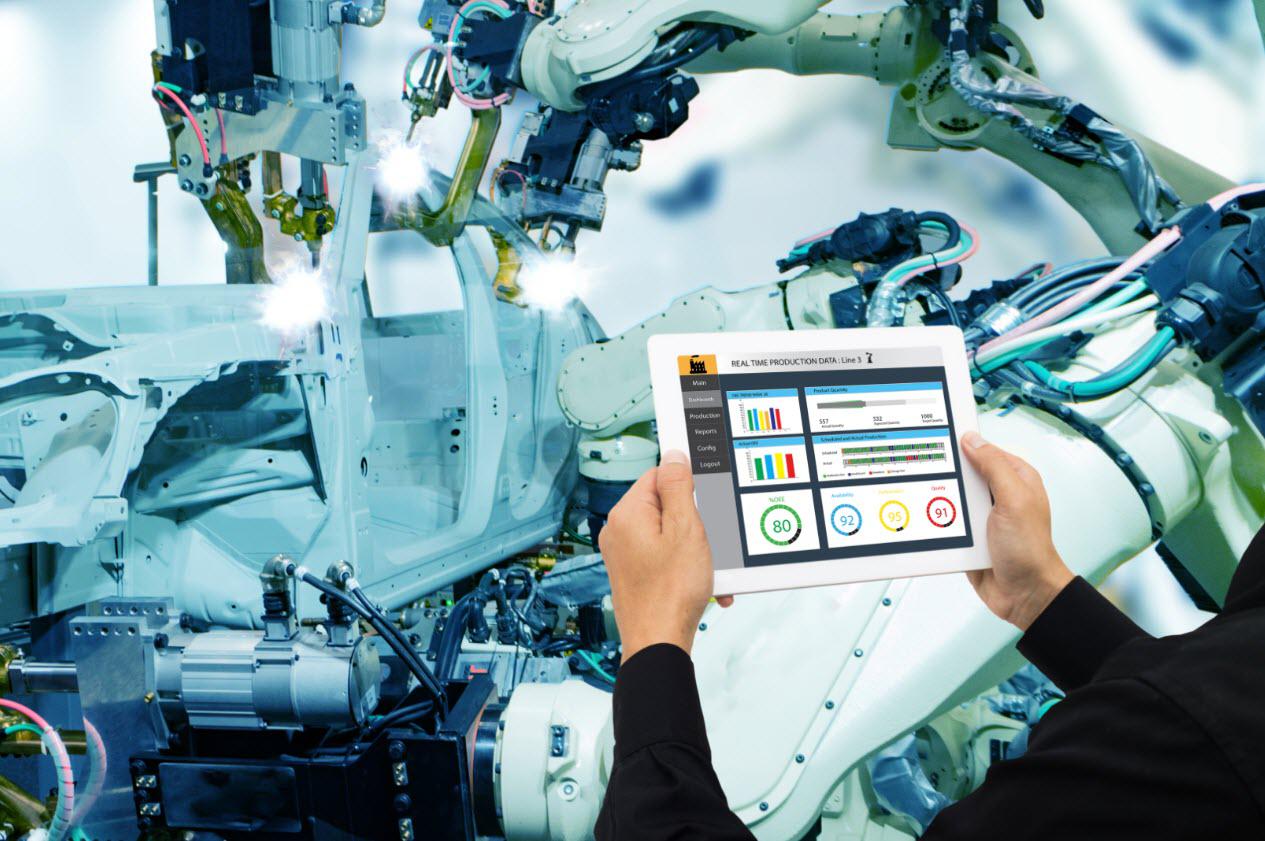

Collaborative Design Process:

The collaborative design process is a hallmark of customized PCB services, fostering close communication between clients and manufacturers. Through iterative feedback and refinement, clients can achieve their desired outcomes while leveraging the expertise of PCB designers and engineers.

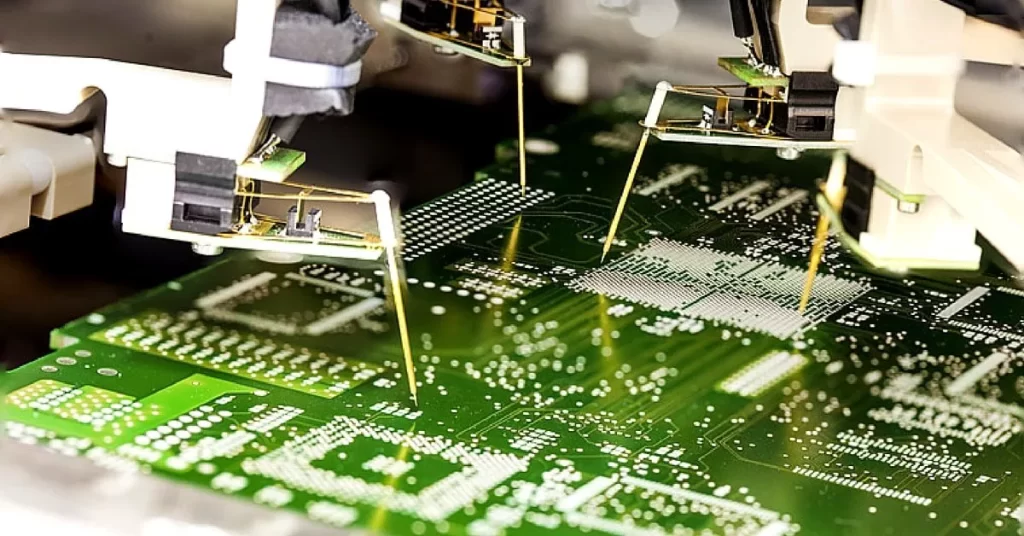

Technical Expertise and Innovation:

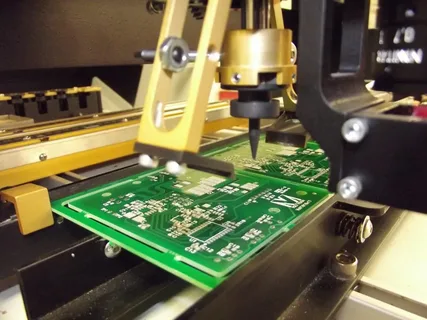

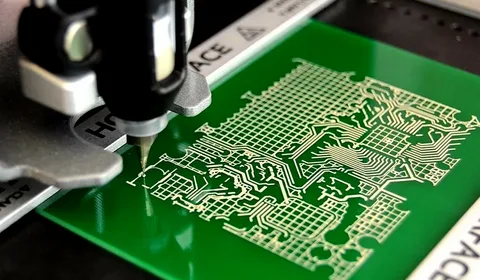

Leveraging advanced technologies and industry expertise, customized PCB services drive innovation. From high-speed signal integrity to miniaturization and thermal management, these solutions meet the evolving demands of modern electronics.

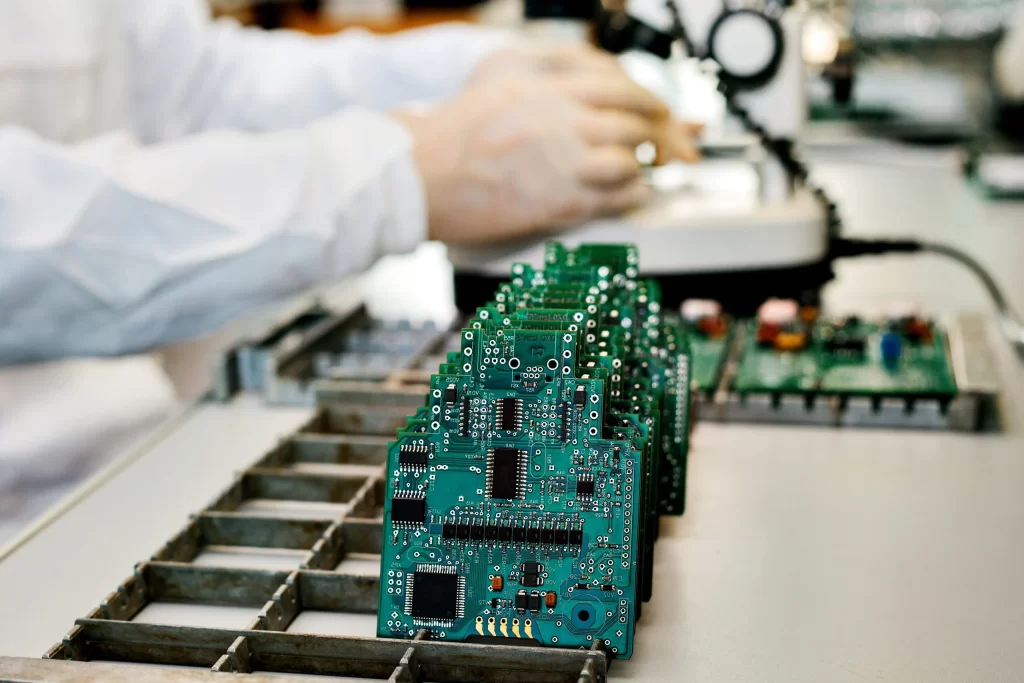

Quality Assurance and Compliance:

Ensuring quality and compliance is paramount in PCB ODM services. Rigorous testing procedures, adherence to industry standards, and certifications such as ISO and IPC ensure that the final products meet the highest quality standards and regulatory requirements.

Case Studies and Success Stories:

Illustrative case studies and success stories showcase the effectiveness of PCB ODM services in real-world scenarios. From consumer electronics to automotive and aerospace applications, these examples highlight the versatility and impact of customized PCB solutions.

Data:

| Feature | Description |

|---|---|

| Customization | Tailored design solutions |

| Quality | Rigorous testing and compliance |

| Innovation | Advanced technologies |

| Collaboration | Client-manufacturer partnership |

| Success Rate | Demonstrated by case studies |

Conclusion:

In essence, customized solutions drive innovation and success in electronics manufacturing. Through collaborative design, technical expertise, and stringent quality assurance, manufacturers deliver excellence efficiently. With a commitment to innovation and client satisfaction, these services shape the future of electronic product development and manufacturing.