目录

TogglePCB Assembly Techniques: Soldering Methods and Challenges

Introduction to PCB Assembly Techniques

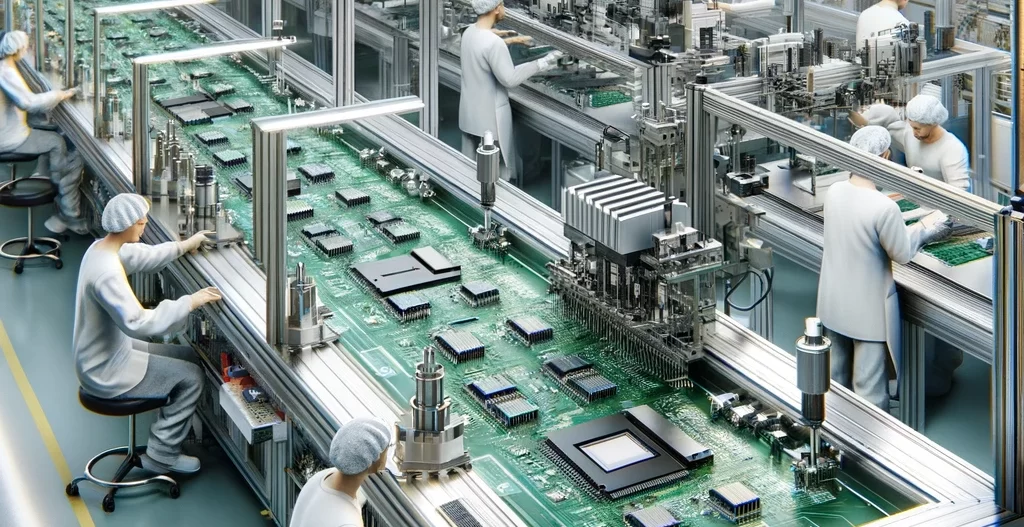

PCB (Printed Circuit Board) assembly is a critical process in electronics manufacturing, involving various soldering methods and techniques. This article explores these methods and the challenges faced during the assembly process.

Soldering Errors and Misalignments in PCB Assembly

One of the primary challenges in PCB assembly is avoiding soldering errors and component misalignments. We examine common issues and how they impact the functionality of the final product.

Advanced Testing and Quality Assurance

Quality assurance is essential in PCB assembly. This section highlights the role of advanced testing methods in ensuring the reliability and performance of PCBs.

Tools and Equipment in PCB Assembly

A variety of tools and equipment are used in PCB assembly, from traditional soldering irons to sophisticated automated machines. Here, we showcase these tools and their applications in the assembly process.

Packaging and Final Preparation of PCBs

The final stage of PCB assembly involves packaging and preparing the PCBs for shipment. This part captures the process of getting the finished products ready for delivery to customers.

Conclusion

PCB assembly is a complex process that requires precision, advanced technology, and rigorous quality control. Understanding the various techniques and challenges involved is key to manufacturing high-quality electronic components.

-

Optimizing Signal Integrity in Multi-layer PCBs for High-Speed Data Transfer

-

Optimizing Thermal Management in High-Density PCB Layouts

-

Advanced Techniques in High-Frequency PCB Design for 5G Applications

-

Eco-Friendly Approaches in PCB Manufacturing: Reducing Environmental Impact

-

Emerging Trends in PCB Manufacturing: From Traditional Methods to Cutting-Edge Innovations