目录

ToggleMastering the Art of PCB Assembly: Essential Soldering Techniques

Setting Up Your Soldering Workspace

A well-organized workspace is key to successful PCB assembly. It should include a reliable soldering iron, quality solder, flux, and a PCB holder to secure the board during soldering.

The Basics of Soldering a PCB

Effective soldering starts with the right technique. It involves heating the joint adequately before applying solder and ensuring the solder flows smoothly around the connection.

Soldering Surface-Mount Devices (SMDs)

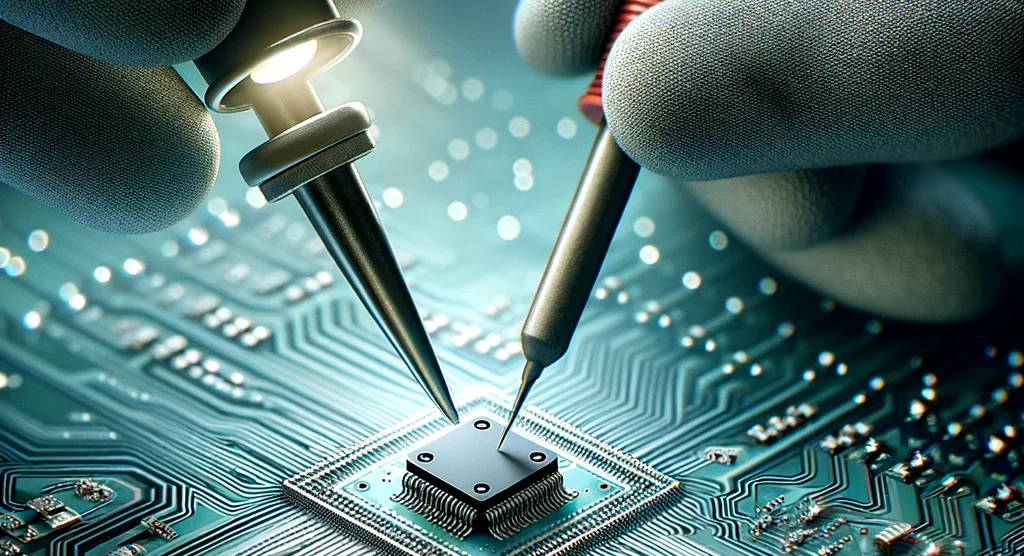

Soldering SMDs requires precision. It’s important to align and place the SMD correctly on the PCB pads before applying heat and solder to create a secure bond.

Quality Assurance in Soldering

Inspecting solder joints is crucial for quality assurance. A magnifying lamp or microscope can be used to check for cold joints, solder bridges, or insufficient solder.

Avoiding Common Soldering Mistakes

Common mistakes like solder bridges or excessive solder can be avoided by controlling the amount of solder and using the correct soldering temperature.

Conclusion

Mastering PCB soldering is about understanding the fundamentals, practicing precision, and constantly learning from experience. With these tips, you can enhance the quality and reliability of your PCB assemblies.