目录

ToggleIntroduction to Heat Management in PCBs

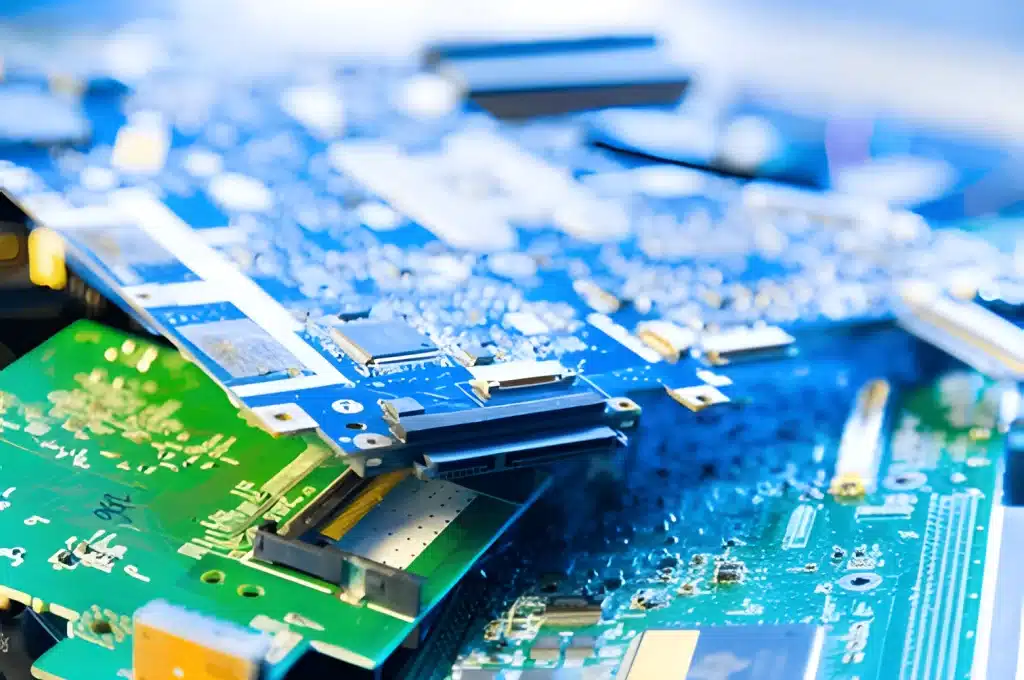

Printed circuit boards (PCBs) are the backbone of modern electronics, providing the necessary pathways for electrical signals to travel between components. As such, they are essential for the functioning of any electronic device. However, due to the high levels of electrical current that passes through them, PCBs can generate a significant amount of heat. This heat can cause components to overheat and malfunction, leading to device failure. Therefore, it is essential for PCBs to have effective heat management systems in place to ensure that the components remain within their safe operating temperature range.

The Role of Copper Weight in Heat Management

One of the most important aspects of heat management in PCBs is the copper weight. Copper is an excellent conductor of heat, and as such, it is used to create pathways for heat to travel away from components and dissipate into the environment. The copper weight of a PCB is determined by the amount of copper used in the board’s design. The more copper used, the higher the copper weight and the better the heat management.

Analyzing the Influence of Copper Weight on Heat Management

The influence of copper weight on heat management can be analyzed in several ways. First, it is important to consider the thermal conductivity of the copper used in the PCB. Copper has a thermal conductivity of 401 W/mK, which is significantly higher than other materials such as aluminum (237 W/mK) and FR4 (0.25 W/mK). This means that copper is able to transfer heat away from components more efficiently than other materials, making it an ideal choice for heat management.

Second, it is important to consider the thickness of the copper used in the PCB. The thicker the copper, the more efficient it is at transferring heat away from components. However, thicker copper also increases the cost of the PCB, so it is important to strike a balance between cost and performance.

Third, it is important to consider the layout of the copper on the PCB. The layout of the copper determines how efficiently heat is transferred away from components. For example, a well-designed layout with multiple vias and ground planes can help to spread heat more evenly across the board, reducing the risk of hotspots.

Finally, it is important to consider the total copper weight of the PCB. The total copper weight is determined by the amount of copper used in the board’s design. The higher the copper weight, the better the heat management. However, it is important to note that too much copper can lead to increased costs and decreased performance.

Conclusion and Recommendations

In conclusion, copper weight plays an important role in heat management in PCBs. Copper has a high thermal conductivity, making it an ideal choice for heat management. The thickness of the copper, the layout of the copper, and the total copper weight all have an influence on the efficiency of heat transfer. Therefore, it is important to strike a balance between cost and performance when selecting the copper weight for a PCB. Additionally, it is important to consider the thermal requirements of the components when selecting the copper weight, as this will ensure that the components remain within their safe operating temperature range.

PCB Fabrication

https://www.facebook.com/profile.php?id=100086889766737