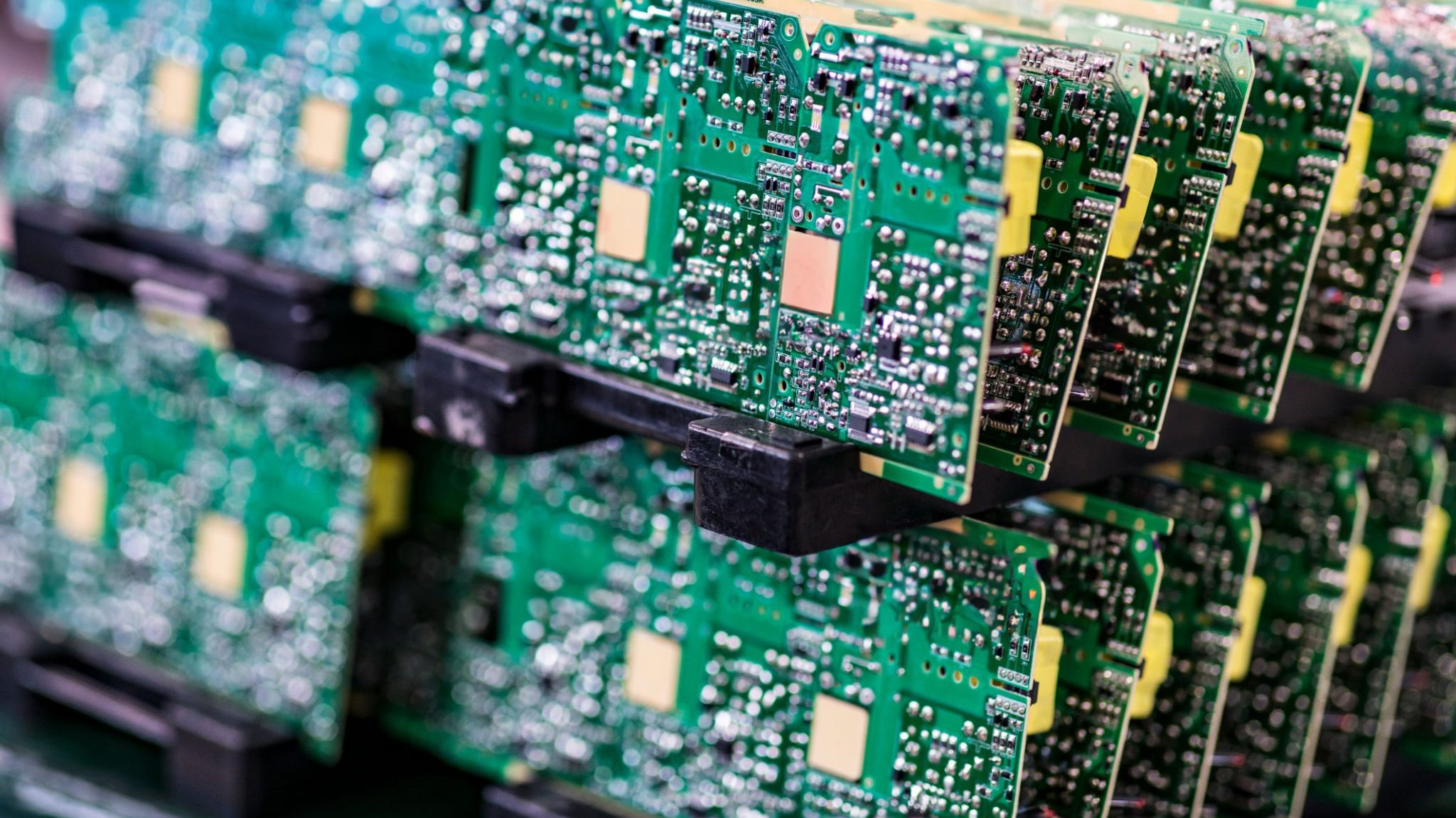

FR4 is a type of material used in PCB manufacturing. It is a flame-resistant, fiberglass-reinforced epoxy laminate that is commonly used in the production of printed circuit boards (PCBs). is the most widely used material in PCB fabrication and is known for its durability and reliability. In this article, we will look at the benefits of for PCB manufacturing and why it is the preferred material for PCBs.

目录

ToggleWhat is FR4 Material?

FR4 is a type of material used in PCB manufacturing. It is a flame-resistant, fiberglass-reinforced epoxy laminate that is commonly used in the production of printed circuit boards (PCBs). is the most widely used material in PCB fabrication and is known for its durability and reliability.

Benefits of FR4 for PCB Manufacturing

FR4 is a highly reliable material for PCB manufacturing due to its high insulation resistance, flame retardancy, and excellent mechanical strength. It is also highly resistant to moisture, temperature, and chemicals, making it ideal for use in harsh environments. Furthermore, is relatively inexpensive compared to other materials, making it a cost-effective choice for PCB manufacturers. Additionally, is easy to work with, allowing for fast prototyping and production.

In conclusion, is an ideal material for PCB manufacturing due to its high reliability, low cost, and ease of use. It is the most widely used material in the industry and is known for its durability and reliability. As such, it is the preferred material for PCBs and is used in a variety of applications.

https://www.facebook.com/people/Topfast-Technology-Co-Ltd/100086889766737/