Optimizing Thermal Management in High-Density PCB Layouts

Introduction

In high-density PCB layouts, effective thermal management is critical to maintain optimal performance and prevent component failure. As electronics become more compact and powerful, the heat generated can pose significant challenges. This article explores various techniques and strategies for mitigating thermal management challenges in high-density PCB designs. Understanding and implementing these strategies can significantly enhance the reliability and longevity of electronic devices.

Importance of Thermal Management in PCB Design

Thermal management in PCB design is essential to ensure that electronic components operate within their specified temperature ranges. Excessive heat can lead to performance degradation, reduced lifespan, and even catastrophic failures. For high-density PCBs, where components are packed tightly together, the risk of overheating is even higher. Implementing effective thermal management strategies, such as heat sinks, thermal vias, and proper airflow, can mitigate these risks and enhance overall device performance.

Techniques for Effective Heat Dissipation

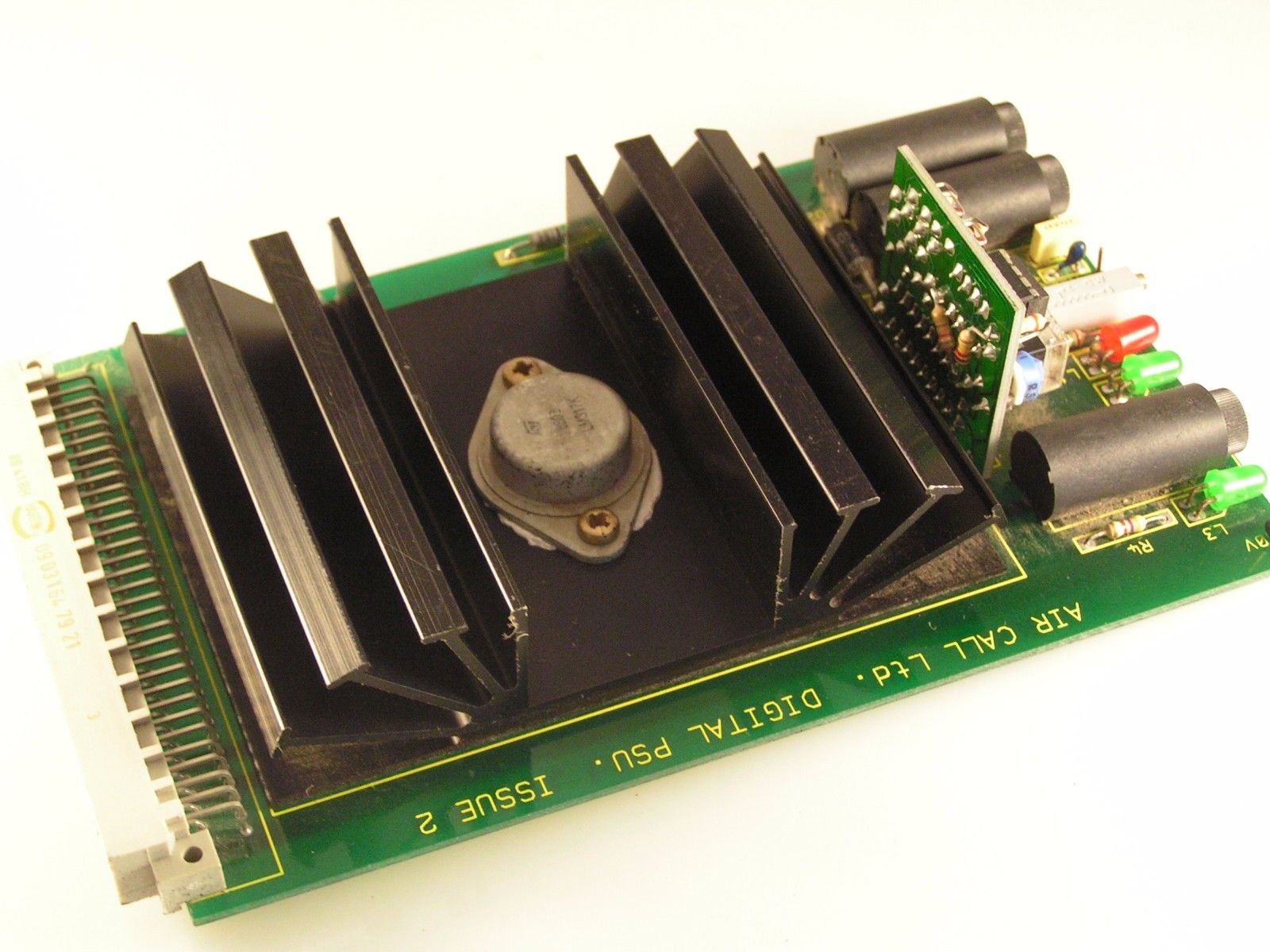

Heat Sinks and Spreaders

Heat sinks and spreaders are crucial for diverting heat away from critical components. By attaching these devices to heat-generating components, designers can effectively dissipate heat into the surrounding environment. The choice of material and the design of the heat sink play vital roles in its efficiency.

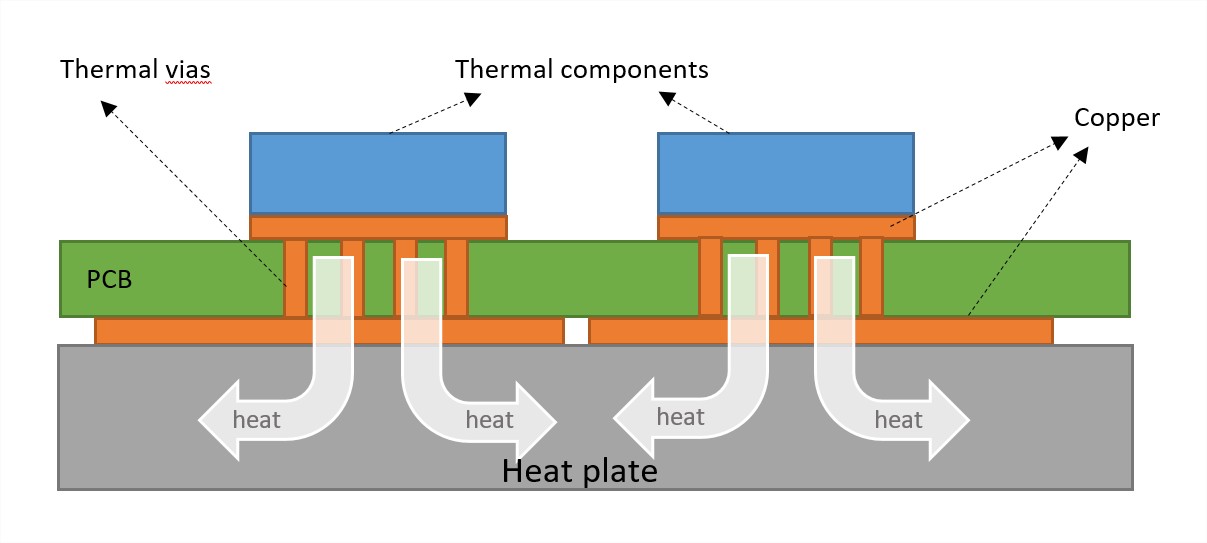

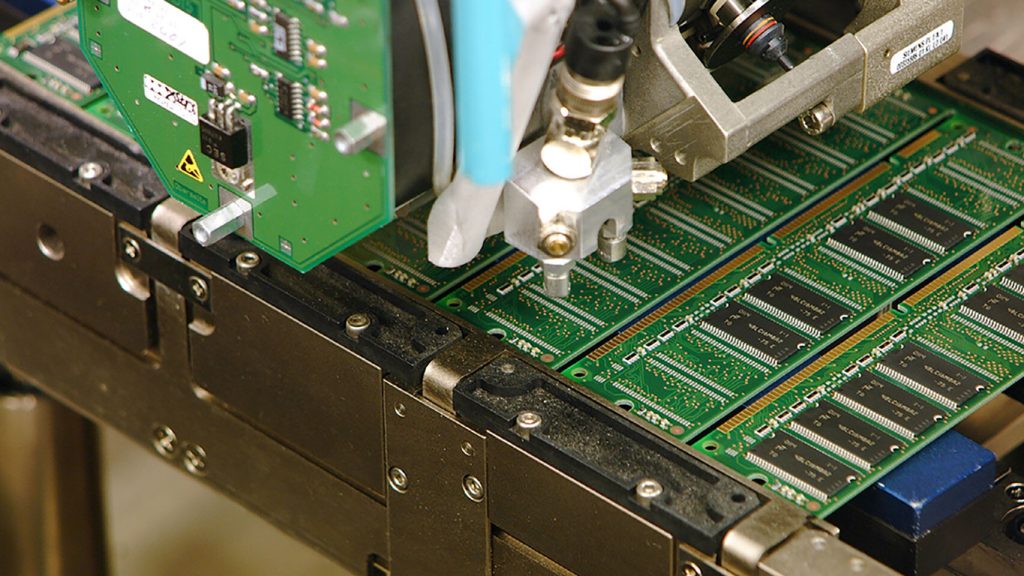

Thermal Vias and Conductive Paths

Thermal vias are another effective method for managing heat in high-density PCBs. These vias allow heat to be transferred from the top layer of the PCB to the bottom layer, where it can be dissipated more efficiently. Additionally, using conductive paths within the PCB can help distribute heat away from hot spots

Advanced Thermal Management Strategies

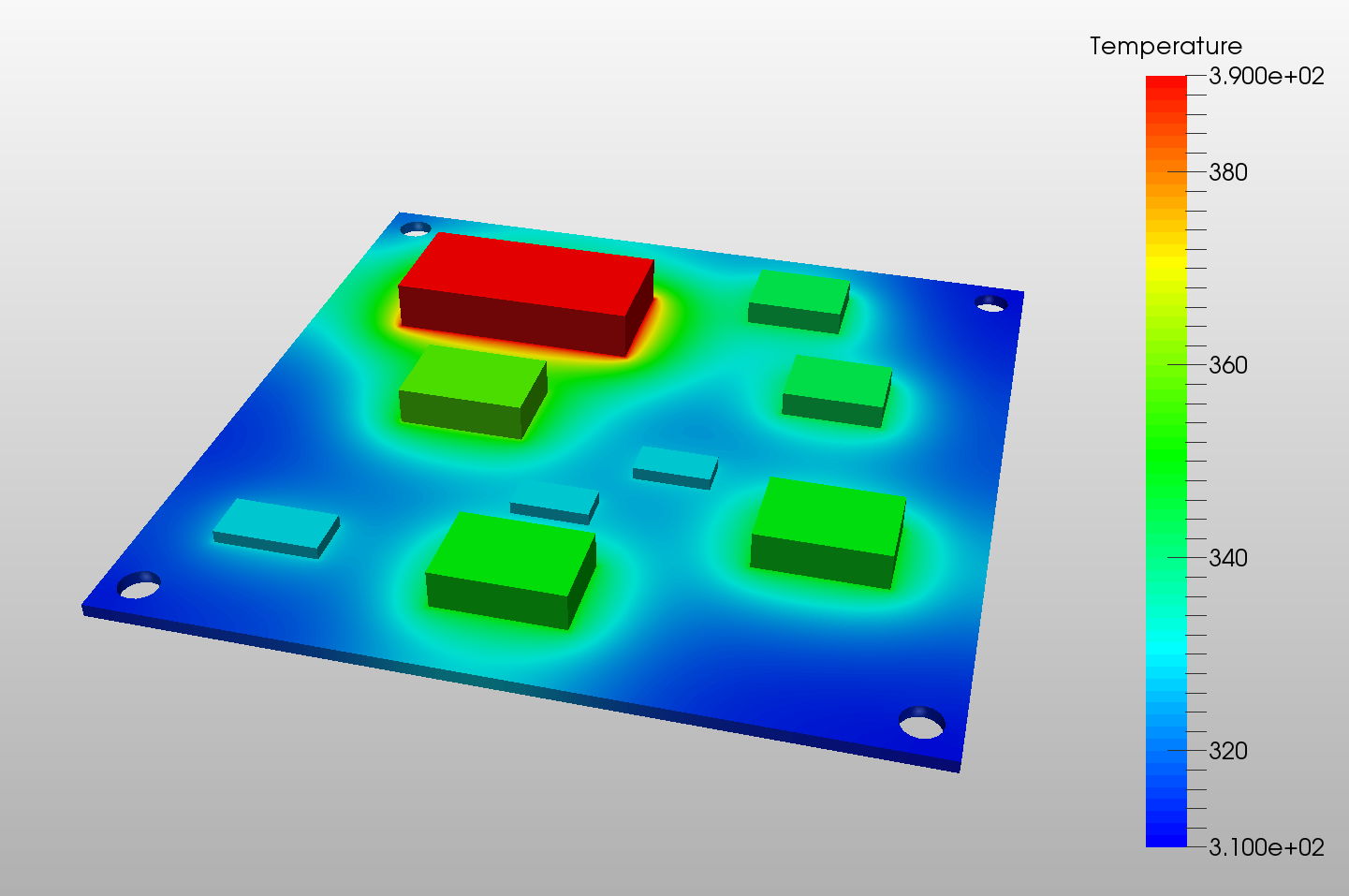

Thermal Simulation and Analysis

Utilizing thermal simulation tools during the design phase can help predict potential thermal issues. These tools allow designers to model heat flow and identify areas that may require additional cooling solutions. By addressing these issues early in the design process, costly redesigns and performance issues can be avoided.

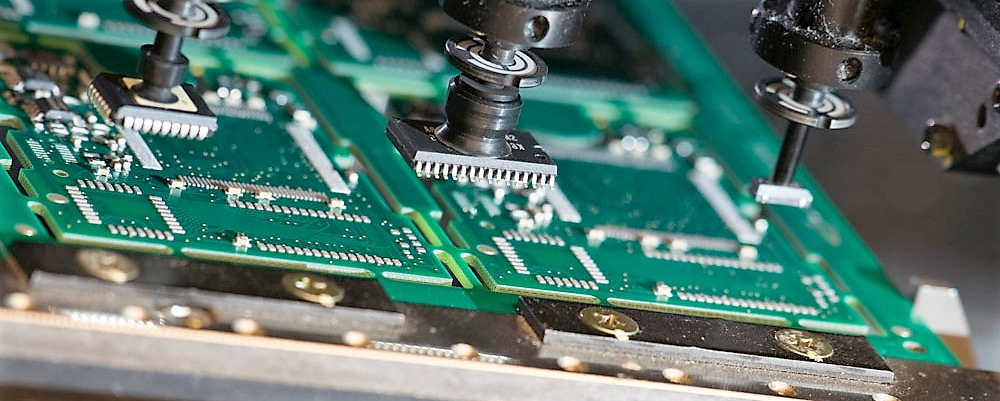

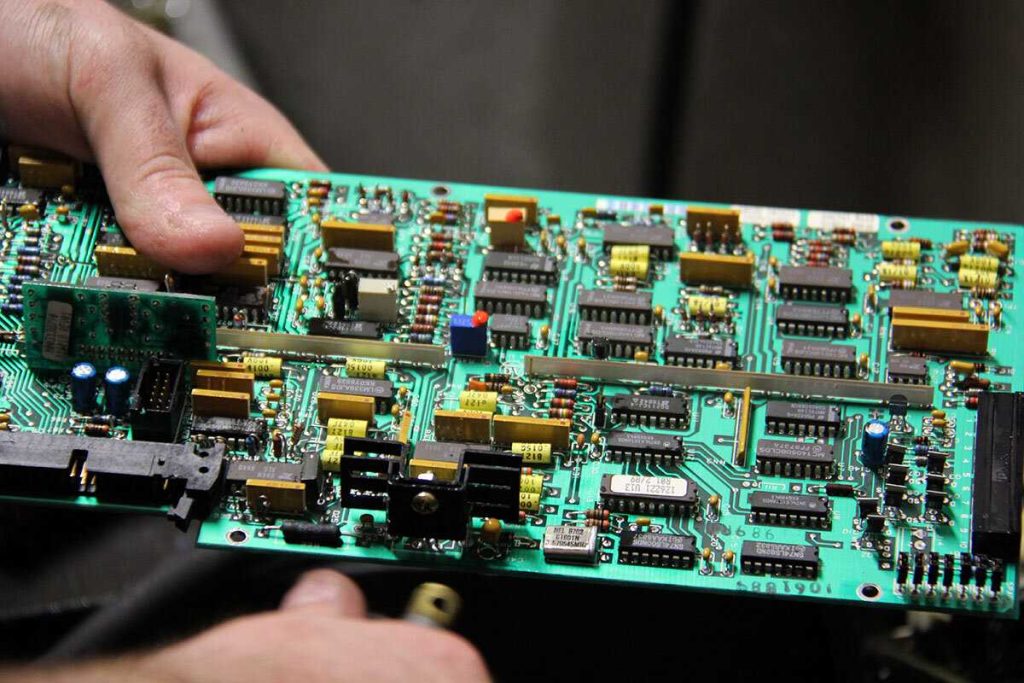

Component Placement and Layout Optimization

Strategic component placement and layout optimization can significantly impact thermal management. Placing heat-sensitive components away from heat-generating components, and ensuring adequate spacing between components, can enhance airflow and heat dissipation. Optimizing the PCB layout for thermal performance requires a balance between electrical performance and thermal considerations.

Material Selection for Enhanced Thermal Performance

The choice of materials in PCB design also influences thermal management. Materials with high thermal conductivity, such as certain ceramics and metals, can improve heat dissipation. Additionally, selecting substrates with low thermal expansion coefficients can reduce mechanical stress caused by temperature changes.

Material |

Thermal Conductivity (W/m·K) |

Applications |

|---|---|---|

|

Copper |

401 |

Traces, heat sinks |

|

Aluminum |

237 |

Heat sinks, spreaders |

|

FR-4 |

0.3-0.4 |

Standard PCB substrate |

|

Ceramic |

20-30 |

High-performance PCBs |

Conclusion

Mitigating thermal management challenges in high-density PCB layouts is essential for maintaining the performance and reliability of electronic devices. By implementing advanced techniques such as heat sinks, thermal vias, and thermal simulation, designers can effectively manage heat and prevent overheating. Material selection and layout optimization further enhance thermal performance, ensuring that devices operate efficiently even in high-density configurations.