目录

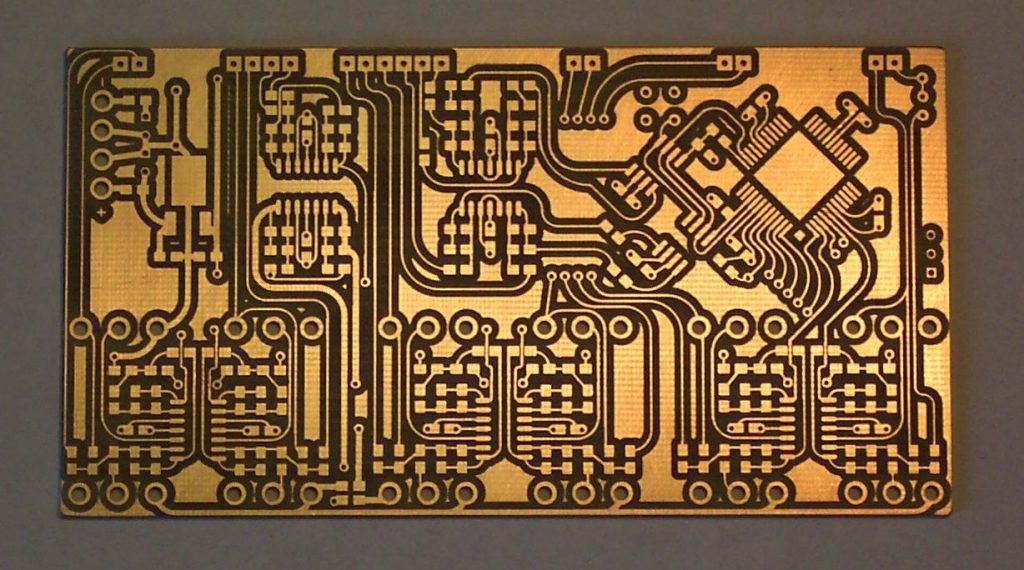

ToggleUnlocking the Mysteries: The Significance of "Gold Plating" on PCBs

Article:

Curiosity often arises among those unfamiliar with PCBs: why is “gold plating” applied to PCBs? While aesthetics play a role, the primary purpose goes beyond mere visual appeal. Let’s delve into the reasons behind the application of “gold plating” on PCBs.

Surface Treatment Options:

PCBs undergo different surface treatments, including anti-oxidation, tin spraying, lead-free tin spraying, gold plating, tin plating, silver plating, hard gold plating, full board gold plating, gold fingers, and OSP. Among these, gold plating PCBs offer distinct advantages and serve specific purposes.

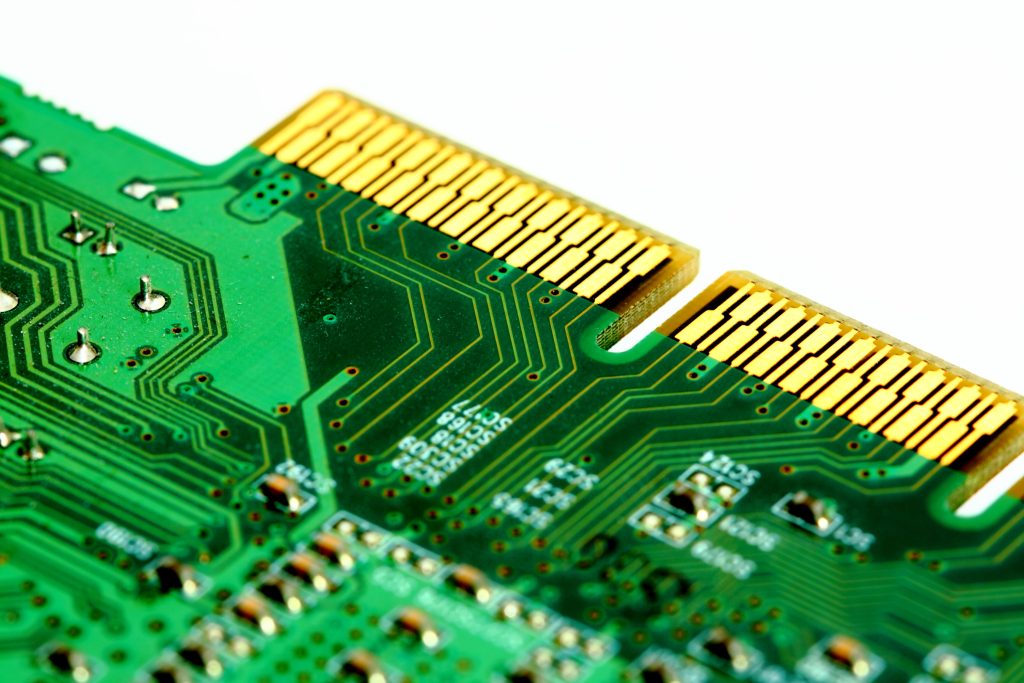

Significance of Gold Fingers:

Gold plating PCBs, particularly on gold fingers, are essential connectors on memory modules, enabling signal transmission between the module and memory slot. These conductive pads are coated with a layer of gold known for its outstanding conductivity and resistance to oxidation.

Why Opt for Gold Plating:

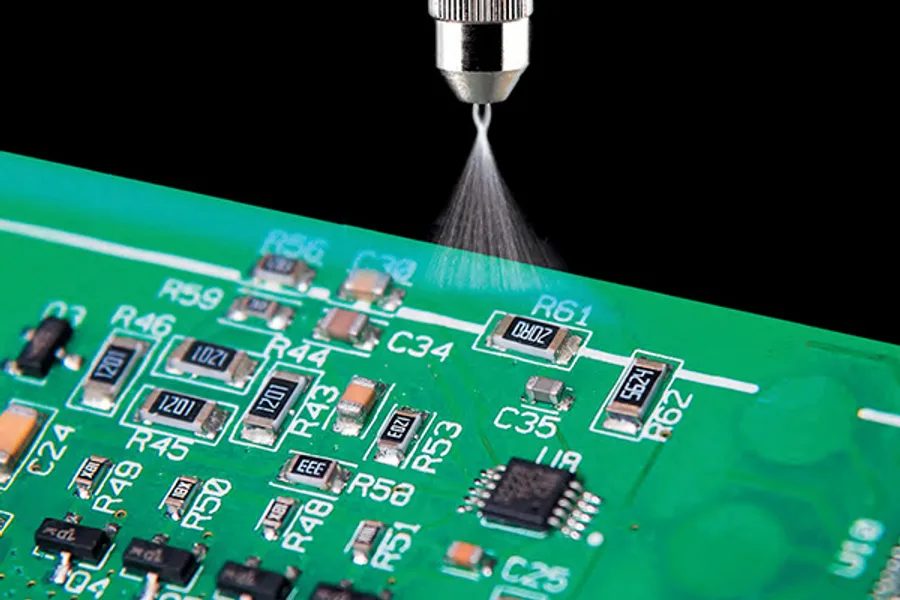

With the increasing complexity of ICs and higher pin densities, traditional tin spraying techniques struggle to flatten finer pads, posing challenges in SMT assembly. Additionally, the short shelf life of tin-sprayed boards complicates production scheduling. Gold plating addresses these issues by providing a flat surface conducive to SMT processes and extending shelf life, making it a preferred choice for high-density and miniature SMT applications.

Exploring the Advantages of Immersion Gold Boards:

Gold plating PCBs provide several advantages compared to traditional surface treatments. Their smooth surfaces guarantee superior soldering quality, especially crucial for ultra-small SMT components. Additionally, their extended shelf life makes them perfect for prototyping stages, balancing cost-effectiveness with performance.

The Shift Towards Immersion Gold:

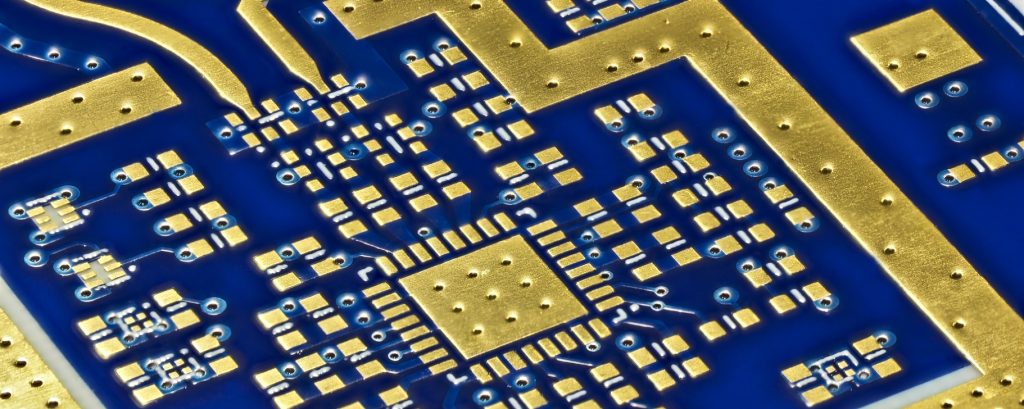

As wiring density increases, thinner trace widths and spacings present challenges like gold wire short circuits. The skin effect, influencing signal transmission in multi-layer boards, becomes more pronounced with higher frequencies. Immersion gold boards, with their unique crystal structure, mitigate these issues, ensuring reliable performance and longevity.

Comparing Immersion Gold and Electroplated Gold:

In PCB manufacturing, both immersion gold and electroplated gold play vital roles. Immersion gold enhances solderability and shelf life, while electroplated gold offers cost-effective options. Manufacturers consider these factors when choosing surface treatments for their Gold Plating PCBs.

Conclusion:

The choice of surface treatment for PCBs involves a careful balance of performance, cost, and manufacturability. By understanding the nuances of different surface treatments like gold plating, manufacturers can optimize PCB designs for various applications, ensuring robust performance and reliability.