目录

ToggleExploring PCB AOI: Automated Optical Inspection in Manufacturing

Introduction to Automated Optical Inspection

PCB AOI, a cornerstone in modern PCB manufacturing, involves the use of cameras and optical systems to inspect PCBs for defects. This technology plays a crucial role in ensuring the quality and reliability of printed circuit boards.

The Role of AOI in Quality Control

In PCB production, maintaining high standards is paramount. AOI systems serve as an essential tool in this process, offering precise and efficient inspection capabilities that surpass manual methods.

Common Defects Detected by AOI Systems

PCB AOI (Automated Optical Inspection) systems excel in detecting various defects in PCBs, such as soldering errors, component misplacement, and circuitry issues. Their role is crucial in ensuring faulty PCBs are identified and corrected before they enter the market.

AOI Technology in Action

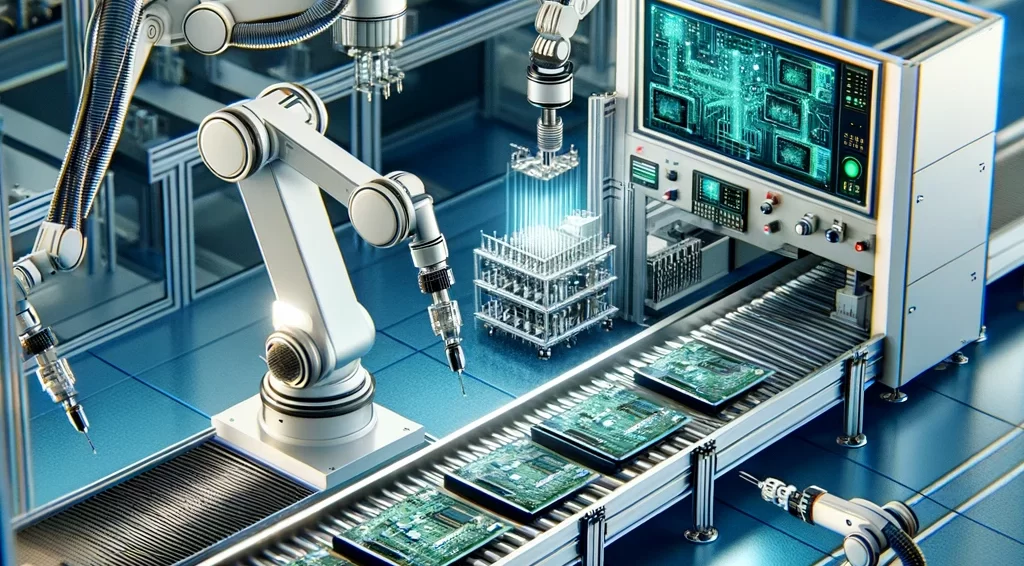

The sophistication of AOI machines, equipped with advanced cameras and robotic arms, allows for thorough and accurate inspection of PCBs in a fast-paced manufacturing environment.

Data Analysis and Reporting in PCB AOI

PCB AOI’s retrofit process: The data collected by AOI equipment is not only used to detect defects, but also to analyze trends and improve manufacturing processes. This data-driven approach improves the overall quality of printed circuit boards.

Conclusion

The integration of Automated Optical Inspection in PCB manufacturing has revolutionized quality control, significantly improving the reliability and efficiency of the production process.

-

Optimizing Signal Integrity in Multi-layer PCBs for High-Speed Data Transfer

-

Optimizing Thermal Management in High-Density PCB Layouts

-

Advanced Techniques in High-Frequency PCB Design for 5G Applications

-

Eco-Friendly Approaches in PCB Manufacturing: Reducing Environmental Impact

-

Emerging Trends in PCB Manufacturing: From Traditional Methods to Cutting-Edge Innovations